VFD Control Panel Manufacturer

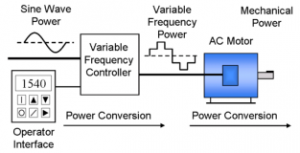

VFD (Variable Frequency Drive) Control panel – An enclosure that protects the VFD and other electric components. Often the work space is dusty, dirty, wet, humid, corrosive, or hot. In such harsh environments, you cannot just mount your VFD exposed. A Variable Frequency Drive (VFD) is a type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the electric motor. Other names for a VFD are variable speed drive, adjustable speed drive, adjustable frequency drive, AC drive, micro drive, and inverter.

What is a VFD control panel used for?

- Keeping all components in one panel.

- Keeping dust, dirt, and weather out of electrical parts.

- A complete motor controlsolution (bypass, harmonic filtering, etc.)

- Pump and fan applications.

- Control and regulation.

- Speeding up or slowing down a machine or process.

- Protection from overload currents.

- Safe Acceleration.

Why should I use a VFD?

1 – Reduce Energy Consumption and Energy Costs

An application that does not need to be run at full speed, then you can cut down energy costs by controlling the motor with a variable frequency drive, which is one of the benefits of Variable Frequency Drives. VFDs allow you to match the speed of the motor-driven equipment to the load requirement. There is no other method of AC electric motor control that allows you to accomplish this. Additionally, the utilization of VFDs improves product quality, and reduces production costs. Combining energy efficiency tax incentives, and utility rebates, returns on investment for VFD installations can be as little as 6 months.

2 – Increase Production through Tighter Process Control

By operating your motors at the most efficient speed for your application, fewer mistakes will occur, and thus, production levels will increase, which earns your company higher revenues. On conveyors and belts you eliminate jerks on start-up allowing high through put.

3 – Extend Equipment Life and Reduce Maintenance

Equipment will last longer and will have less downtime due to maintenance when it’s controlled by VFDs ensuring optimal motor application speed. Because of the VFDs optimal control of the motor’s frequency and voltage, the VFD will offer better protection for your motor from issues such as electro thermal overloads, phase protection, under voltage, overvoltage, etc… When one starts a load with a VFD you will not subject the motor or driven load to the “instant shock” of across the line starting, but can start smoothly, thereby eliminating belt, gear and bearing wear. It also is an excellent way to reduce and/or eliminate water hammer since we can have smooth acceleration and deceleration cycles.

Functions & Features

- Set-up Parameters

- The Control Method Acceleration

- Acceleration-Ramp Rate

- Automatic Restart

- Stopping Method Automatic Signals

Applications

- Water Supply Pump Application

- Conveyor Application

- Exhaust Fan Application

- Compressor Application